Arc Flash Information

ARC FLASH STUDY

Arc Flash studies can help improve plant safety by identifying specific arc flash hazard at a given piece of equipment.

What is an Arc Flash?

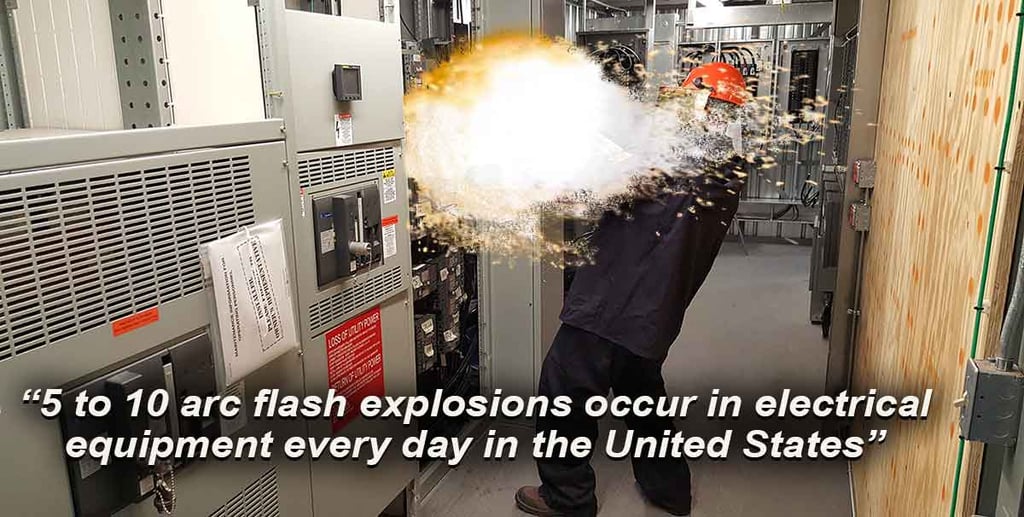

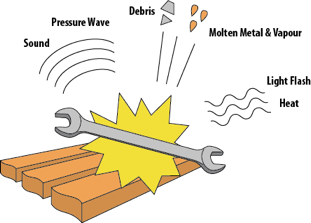

An Arc Flash is an EXPLOSION! Contrary to what many people believe, an Arc Flash is NOT an Electric Shock. It is an occurrence in which electrical current flows through the air from one conductor to another, or to ‘ground’ in an electrical system. It happens when there is a breakdown of electrical impedance in the air around a conductor. While air resistance is low, and there is enough voltage present in the conductor, the voltage can make its own path which arcs through the air to a nearby conductor or ground. Read 8 Alarming Facts about Arc Flash Safety.

An Arc Flash is an EXPLOSION! Contrary to what many people believe, an Arc Flash is NOT an Electric Shock. It is an occurrence in which electrical current flows through the air from one conductor to another, or to ‘ground’ in an electrical system. It happens when there is a breakdown of electrical impedance in the air around a conductor. While air resistance is low, and there is enough voltage present in the conductor, the voltage can make its own path which arcs through the air to a nearby conductor or ground. Read 8 Alarming Facts about Arc Flash Safety.

What causes an Arc Flash?

An Arc Flash incident can have numerous causes. Dust or corrosion on the surface of a conductor, dropped tools, accidental touching, condensation, material failure, improperly designed or utilized equipment, and improper work procedures can all lead to dangerous arc flash accidents.

How do Arc Flash incidents affect businesses?

The legal and financial consequences of noncompliance, or worse, an arc flash accident, include hefty OSHA fines,expensive repairs, personal injury lawsuits and brief facility shutdowns. Much worse, however, is that these incidents can take from companies their most valuable asset, their employees. Especially depending on whether or not victims survive, and whether or not they desire to return to work after recovery. The morale of other employees also tends to depreciate greatly, as it can be very shocking for people to witness an arc flash incident resulting in the injury or death of a fellow coworker. The only way to properly mitigate the risks associated with Arc Flash incidents is to have an Arc Flash Study performed.

Why do you need an Arc Flash study?

An arc flash study is a risk analysis that is performed by an electrical engineer. A correctly executed study can help improve plant safety by identifying the specific arc flash hazard at a given piece of equipment. It identifies the Arc Flash Protection Boundary, which is the closest approach allowed before PPE must be worn. Follow the button below to read more about the PCX Arc Study.

Free E-Book

Step-by-Step Guide to Performing Arc Flash Studies

Did you know that approximately five burns a day are treated in North America due to arc flash hazards? An effective safety program, which includes an arc flash study, can substantially reduce risk for employees working with live equipment.

Did you know that approximately five burns a day are treated in North America due to arc flash hazards? An effective safety program, which includes an arc flash study, can substantially reduce risk for employees working with live equipment.

Performing an arc flash study – including calculations – can be a daunting task. Our new e-book, “Engineering Challenges of Performing Accurate Arc Flash Studies,” provides a step-by-step guide for performing arc flash studies. Each step has its own criteria for data input, analysis and data output.

In this 15-page e-book, we’ve used tables and software screenshots to help you understand:

Why is Doing an Arc Flash Study so Important?

- Overall Concerns and Challenges

- Industry Standards

- Detailed Breakdown of Each Step

- Analysis of Data

- Common Mistakes

Fill out the form below to find out how you can conduct an accurate arc flash study and protect the safety of your workers.